Built-up vs Carved Beams

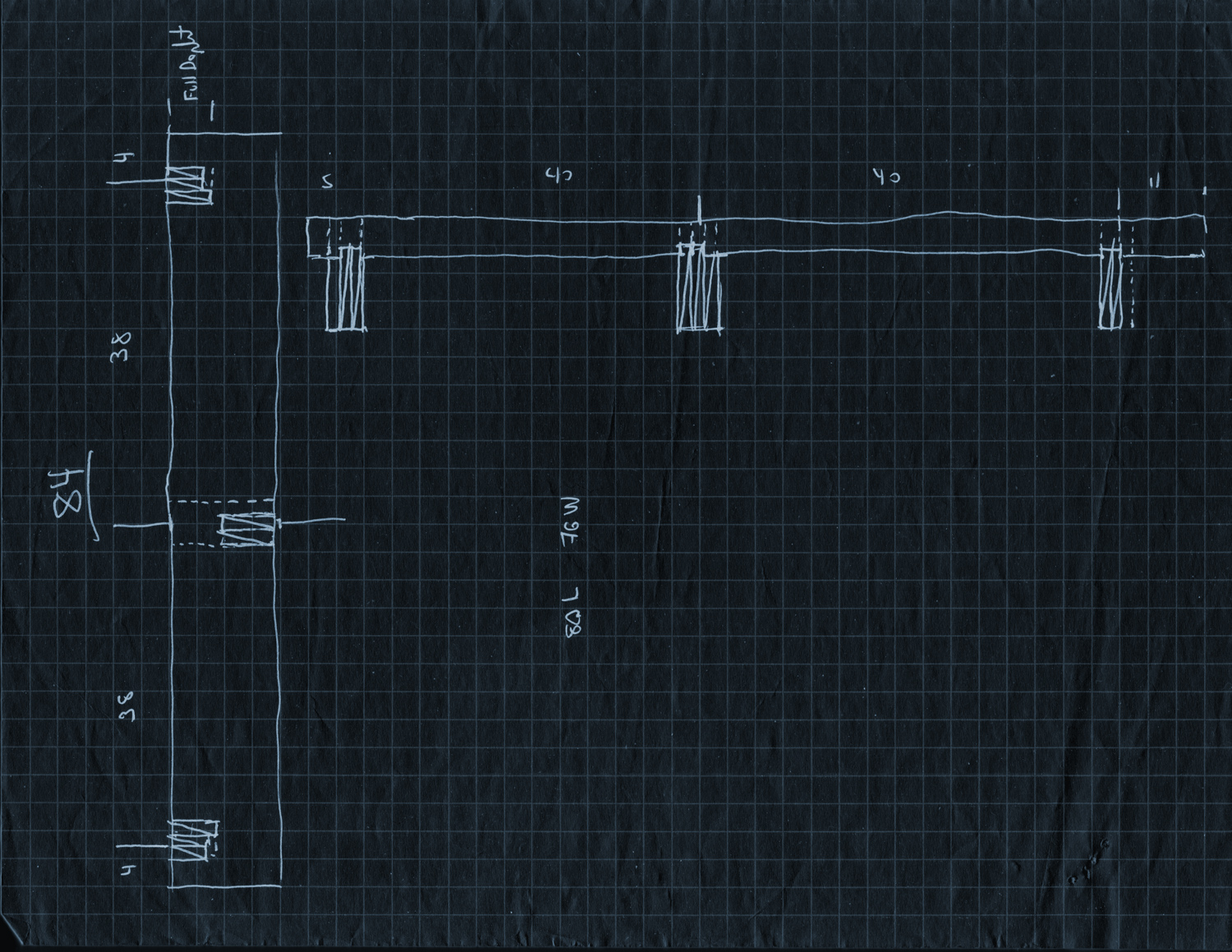

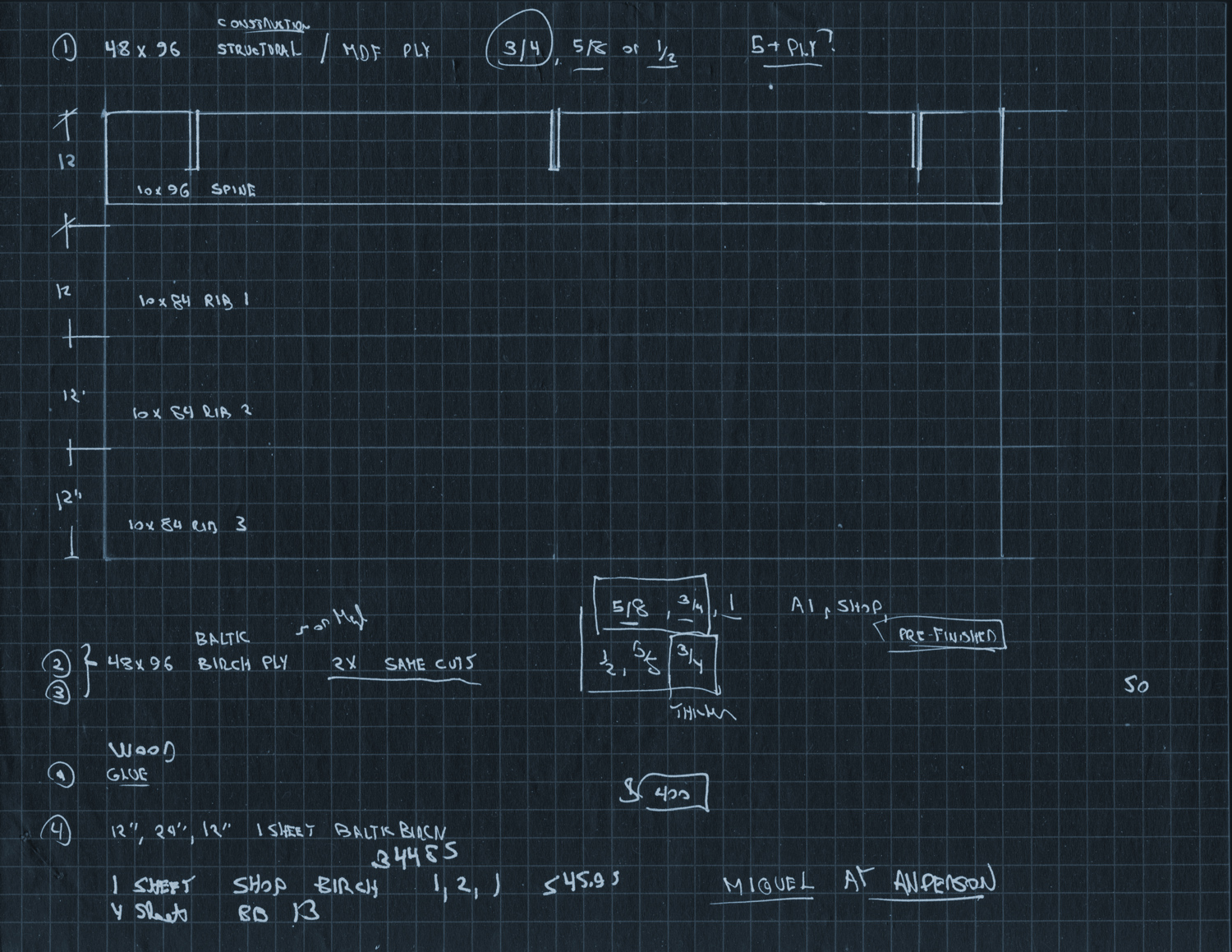

I knew that compared to regular lumber, laminated wood was strong and dimensionally stable through heat and humidity cycles. Also, beams combining 2 or 3 sheets of plywood would have enough thickness to stand upright.

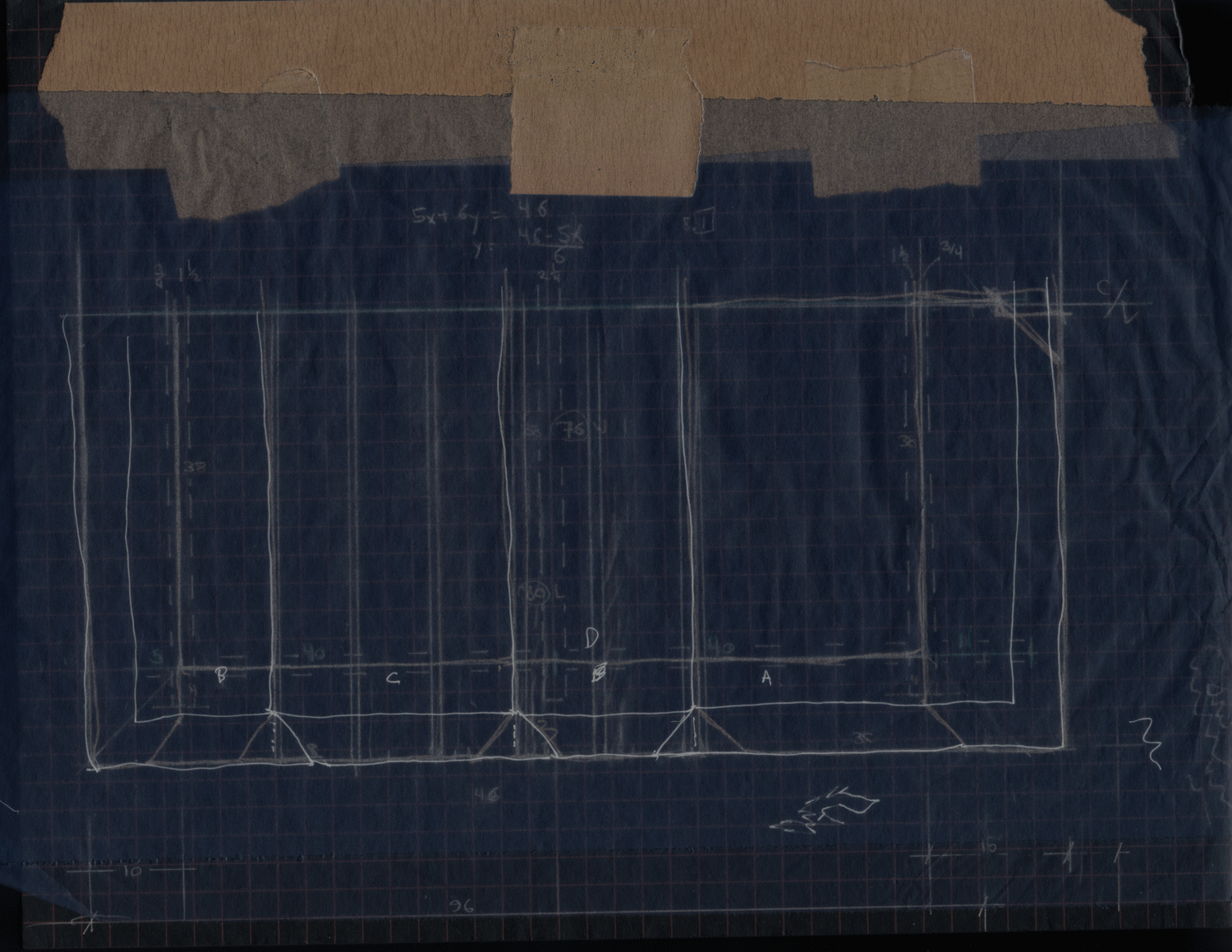

I had seen images of intricate Japanese joints designed to lock perpendicular beams in place. The joints require great skill to precisely carve and chisel. I cutout the joint on each flat sheet of plywood with a jigsaw and chisel. I created the interlocking double dado joint when the pieces get laminated together. Each 3/4 inch thick Europly laminated plywood had 7 plys of thin wood, the combined pieces are 21 ply, so there's significant redundancy.

The beams were laminated together with white carpenter's glue overnight. The assembled beams were routed and sanded to smooth out any splinters and rough edges. Finished beams were sealed with a clear varnish to protect the plywood.

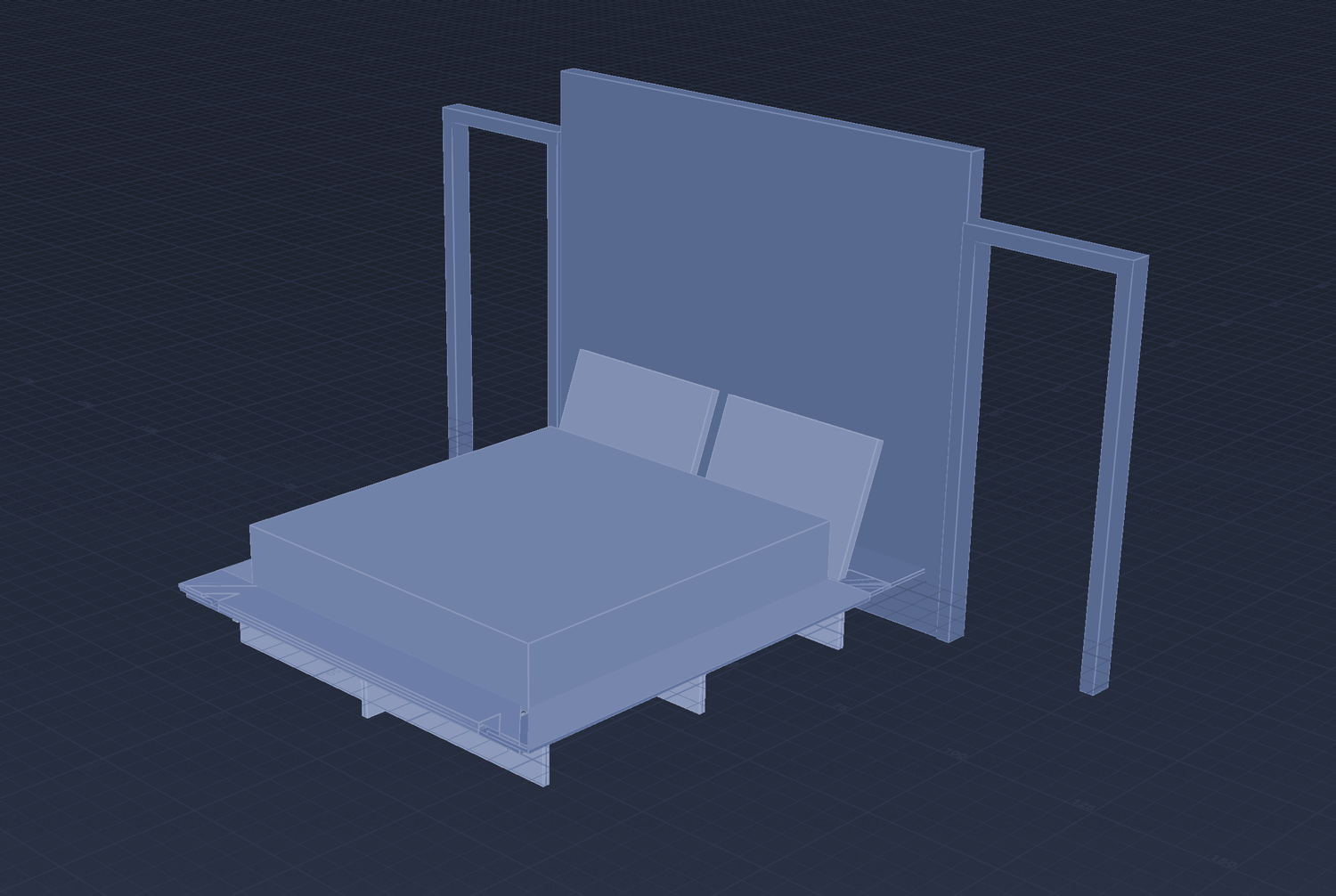

The design of the platform and headboard was refined along the way. The platform used interlocking pieces to prevent sliding. 21 plys are seen on the edge but the sleeping section is only 1 7-ply piece thick. The pieces would have been too heavy to move if they were full thickness throughout.

I was not able to wedge the headboards into the platform. Instead the final design is supported on the back and rests on the platform, locked to prevent tip-overs in an earthquake.

Assembly

Two people are needed to assemble or disassemble the bed. The pieces can be slotted in position without tools. Due to the size and weight of the components it's harder to man handle than an equivalent sized Ikea bed.